Basic requirements for an ideal floor finish are that it should be economical resistant to wear impervious sanitary fire resistant skidproof inert easy to maintain and to clean.

Granolithic flooring mix design.

There are two types of concrete floors used in industrial plants.

The granolithic concrete flooring is laid using rich concrete made with specially selected aggregate of high hardness surface texture and particle shape which is adapted for heavy engineering factories workshops garages warehouses etc.

The granolithic concrete is chosen because of its high abrasion resistance and used for floor toppings wherever abrasion combined with impact is.

Since granolithic toppings have a higher resistance to abrasion and impact than traditional cement sand screeds they can be used in a variety of industrial applications as wearing surfaces without final floor coverings.

For mastic coverings usually require a smoother steel trowelled surface.

Granolithic flooring offers a visually pleasing alternative to traditional concrete.

Granolithic is also known as granolithic paving and granolithic concrete is a type of construction material composed of cement and fine aggregates such as granite or other resistant rocks.

For the construction of granolithic flooring first of all the base concrete which is 2 5 cm thick cement concrete over 10 to 15 cm of lean cement or lime concrete is laid and consolidated before laying the topping.

Description granolithic flooring differs from ordinary concrete flooring in that it uses an aggregate or mix of materials instead of a single uniform cement.

Screeds the surface of the screed should be finished according to the type of wearing surface or flooring that is to be laid.

If a designer specifies the use of a thin sheet or tile floor then.

The mix of cement and aggregate can be polished to a smooth finish and sealed with a durable surface coat.

Placing and finishing the concrete floor to acceptable standards is impracticable.

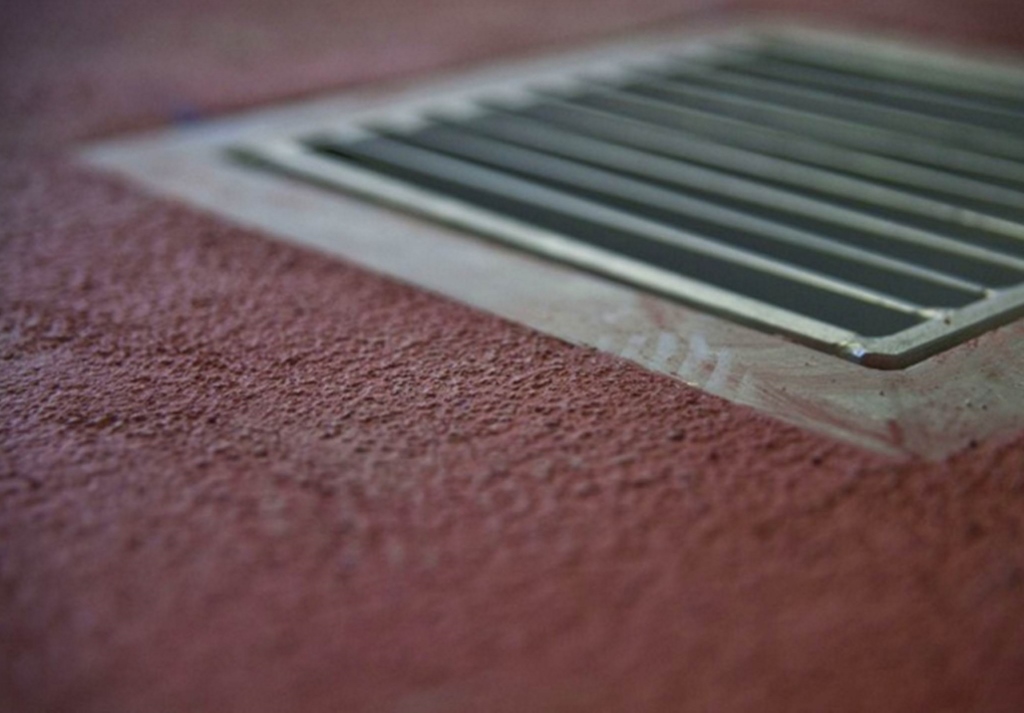

Granolithic screed is a floor topping which is placed on to an existing hard base usually a concrete slab to form a durable top surface.

The minimum thickness of finishing should be 1 2.

Although granolithic flooring can sometimes make a room feel cold the infusion of texture color and inlaid design can restore warmth to this masonry flooring.

Method of granolithic flooring construction.

The granolithic concrete should be laid before the base concrete has set.

It comprises hard aggregates cement and sand which are blended with water and sometimes polymers to make a workable mix.

What is granolithic flooring.

Traditionally granolithic finishes are used in applications where a sound consistent hard wearing yet inexpensive surface.

The granolithic flooring concrete mix is generally in the proportion of 1 1 2 or 1 1 3.