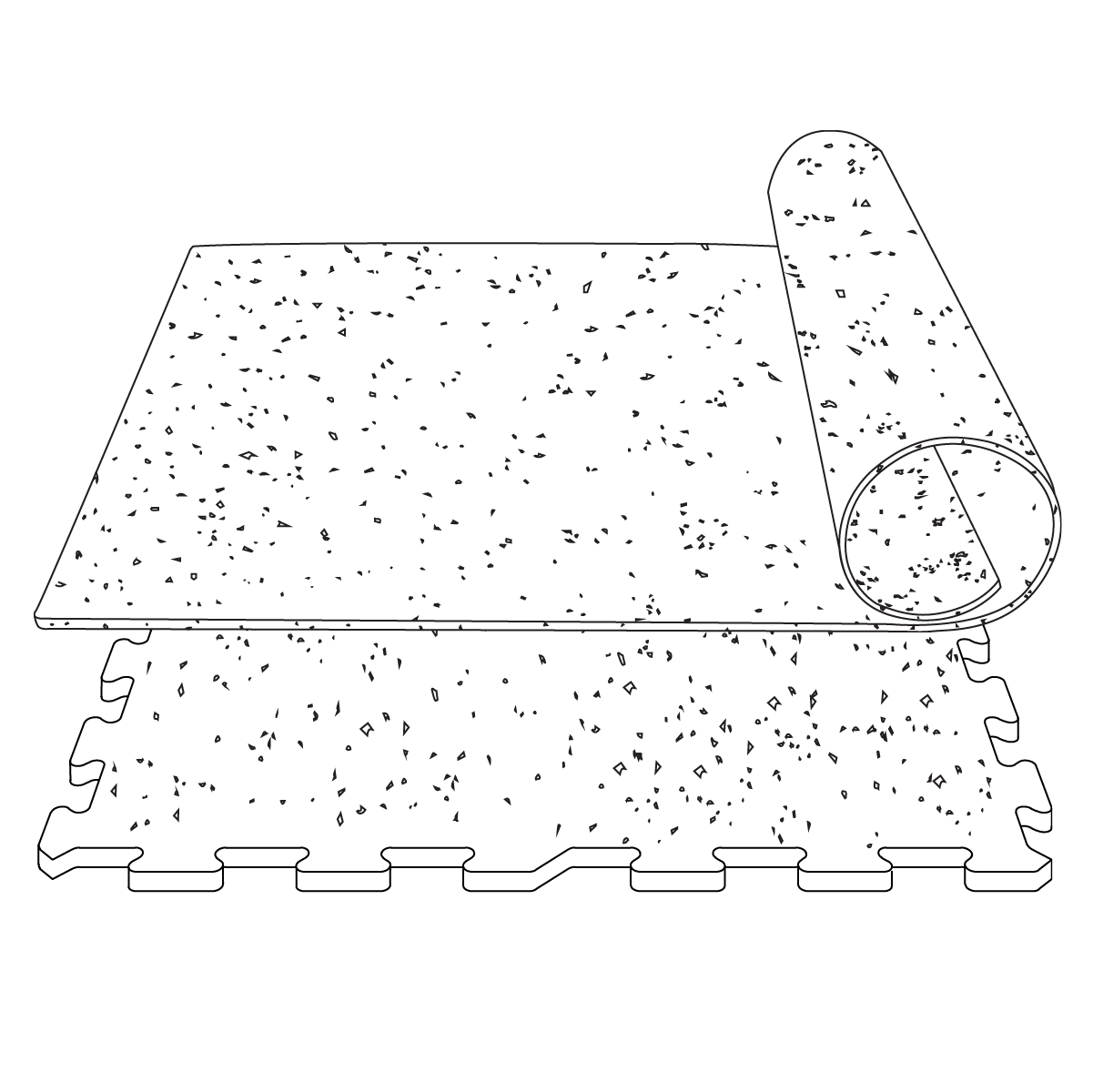

Resilient floor covering made from recycled rubber content and coloured epdm granules used when superior impact shock vibration and noise control is required in fitness gym sports and training facilities and high traffic or acoustically sensitive environments.

Genie mat fit 08.

Geniemat ff70ldm modular product spec guide.

Resilient floor covering made from recycled rubber content and colored epdm granules used when superior impact shock vibration and noise control is required in fitness gym sports and.

Geniemat fit08 fitness floor covering product specification product name.

Geniemat fit floors dramatically reduce low frequency impact noise in free weight areas under cardio equipment and in fitness studios.

Cover seams with standard duct tape.

Geniemat ff75 roll out product spec guide.

Acoustical consultants and engineers can access over 700 acoustical tests using echoone.

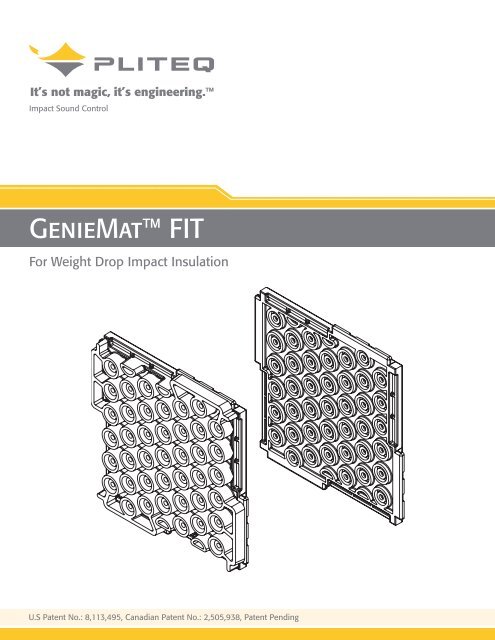

Resilient floor interlocking tile system made from up to 93 recycled rubber content and comprised of resilient floor covering and interdependent hollow core impact pedestals on the underside used when.

Install flooring directly to the geniemat rst or to the additional layering over the geniemat rst if applicable.

Geniemat ff roll out 3 part guide spec.

Geniemat ff50 roll out product spec guide.

Geniemat ff70 modular product spec guide.

Pliteq geniemat fit applications.

Geniemat fit is an all in one fitness floor made from recycled rubber engineered to reduce structure borne sound and vibration transmission in concrete wood frame and metal deck construction.

Registered users are able to access acoustical test reports for more.

High impact studios and free weight dumbbell areas.

The product is on average 8 6 to 10 7kg per m2 allowing for superior control of impact sound and a robust heavy duty and long lasting surface.

Geniemat fit 70 fitness interlocking tile product specification product name.

Geniemat fit08 8 mm description.

Geniemat ff modular 3 part guide spec.

Geniemat fit08 8mm rubber gym flooring is ideal for a wide range of fitness applications.

Roll out the material and cut to fit leaving up to a 1 4 gap on the perimeter.

Pliteq developed a proprietary website called echoone in 2017 for acoustical consultants and engineers.

Fill in gaps with acoustical sealant before taping.